Machining and Production Technology Laboratory

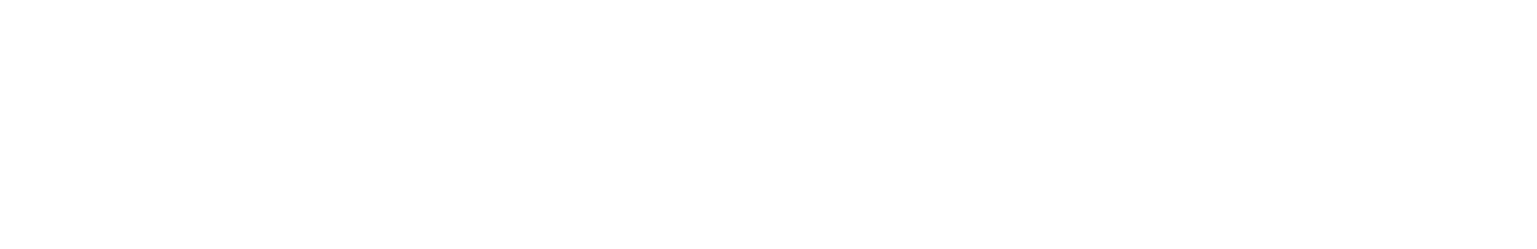

The laboratory researches the cutting process, cutting tools, and both conventional and CNC production machines.

The laboratory is equipped with:

- CNC vertical milling center Hurco VMX30t (4-axis).

- CNC lathe Hurco MT8 (3-axis).

- CNC lathe Mazak NEXUS 100-M (3-axis).

- Kistler Dynamometer.

- Universal lathe SUI 40 (1pc) and milling machine FA4V.

- A semi-automatic band saw BOMAR 320.250 DGH for cutting.

- Vertical milling center STAMA MC325 (3-axis).

- Lathe SN55.

- Power shears NTV 2000/4.

- Thread cutter.

- TIG welding unit.

- Drive unit acceleration head.

- 3D measuring machine MORA.

The laboratory is focused on:

- Studying the cutting process.

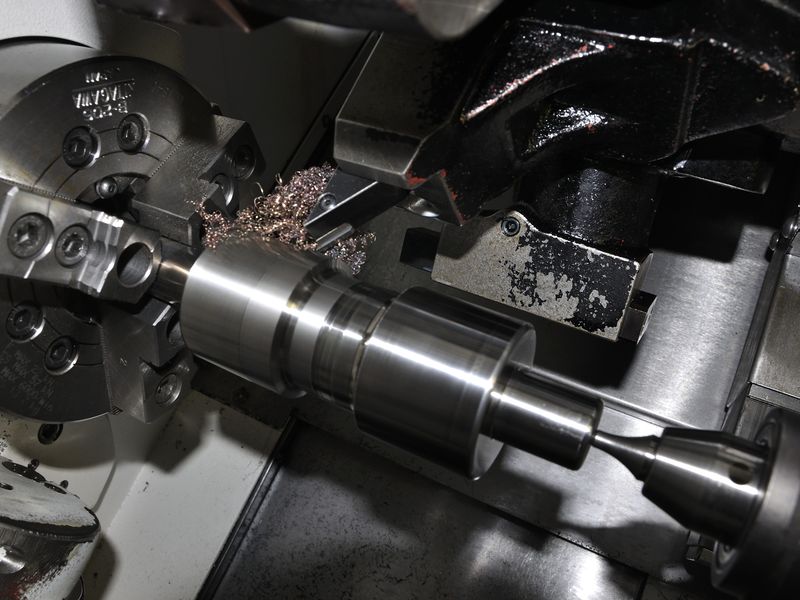

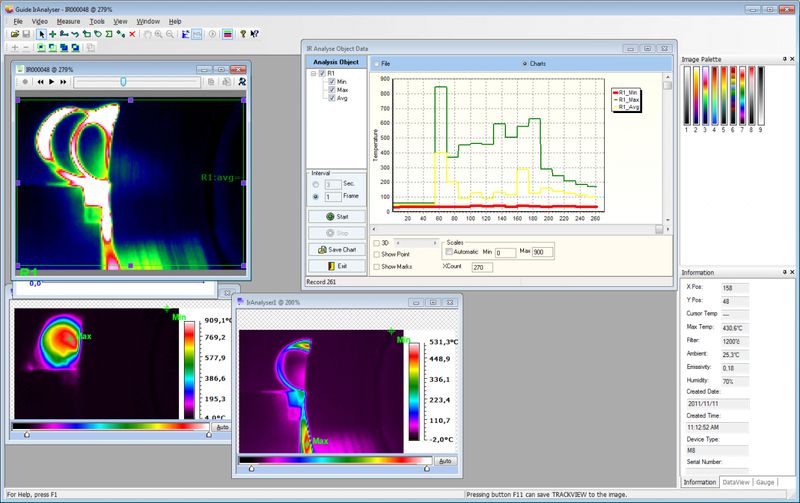

- Researching accompanying phenomena of the cutting process:

-

- Cutting forces in turning, milling, drilling, and grinding.

- Temperatures in the cutting zone.

- Dynamic phenomena in machining.

- Surface quality of the machined part.

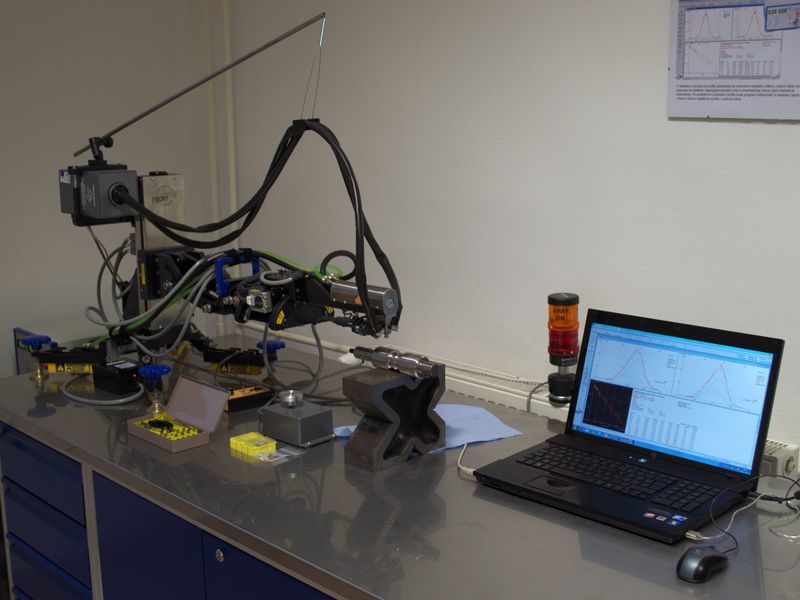

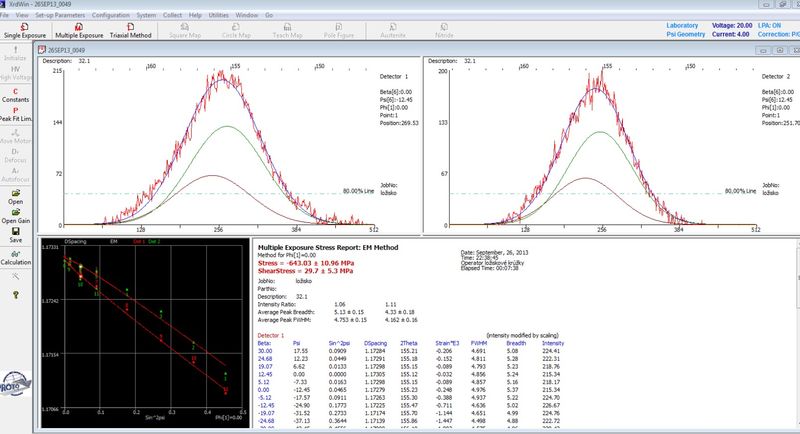

Laboratory of Non-Destructive Technologies

The laboratory is devoted to studying stress states, as well as the mechanical and geometric properties of parts.

The laboratory is equipped with:

- X-ray diffractometer.

- Noise measurement devices.

- Depth gauge for external cracks Karl Deutch RMG 4015.

- Thermal imaging camera Mobir M8.

- Hardness tester TH 160.

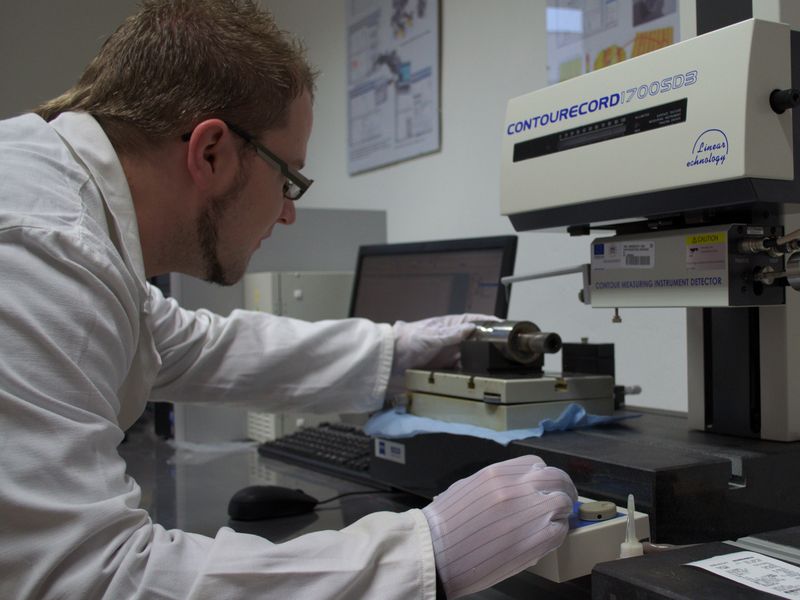

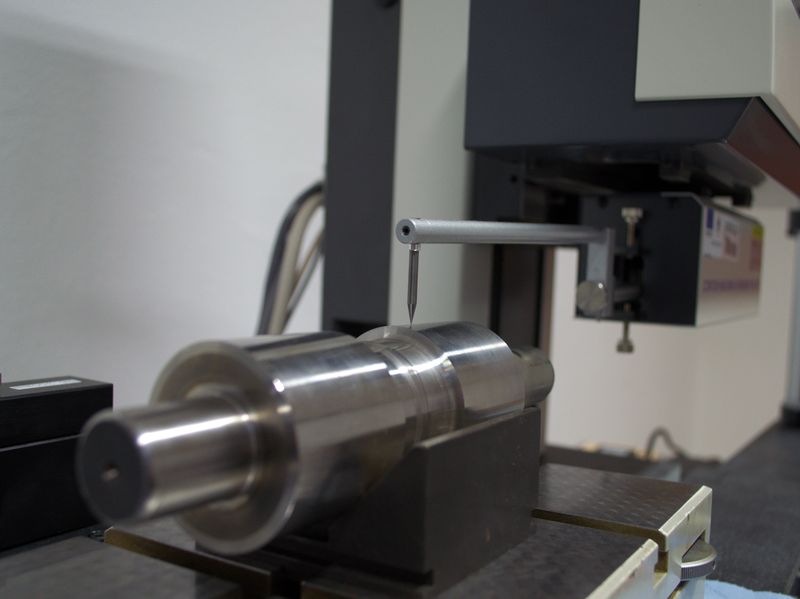

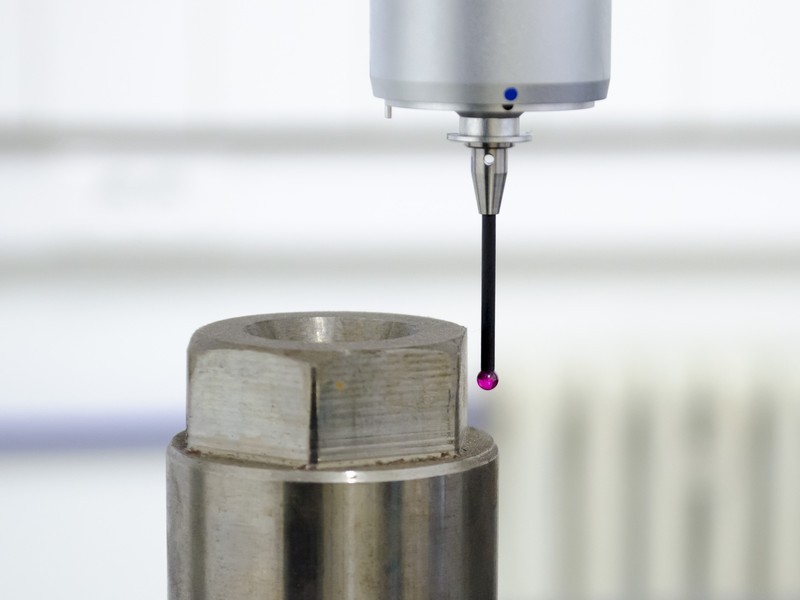

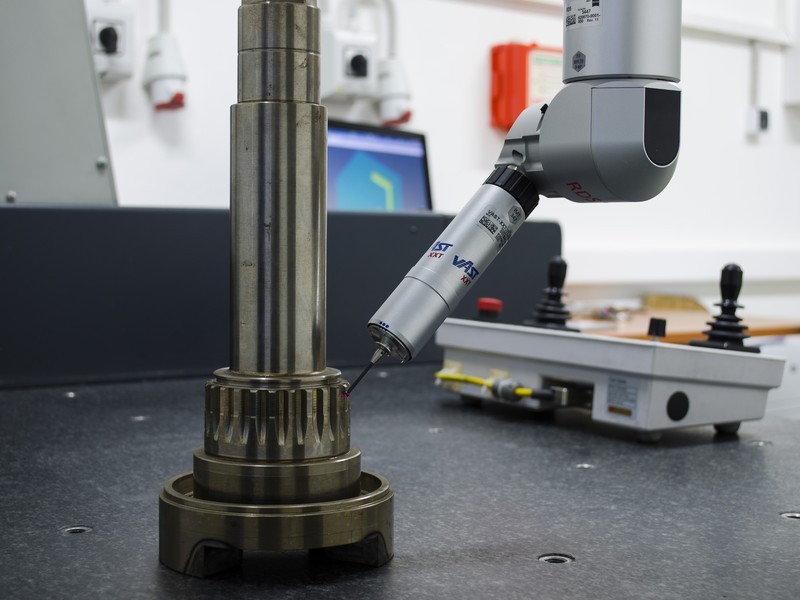

Laboratory of Precision 3D Measurement CMM and Coordinate Measuring Device Accuracy Diagnostics

The laboratory is focused on studying surface and geometric characteristics, primarily employing scanning measurement strategies. It was established in 2015 with the support of Carl Zeiss Slovakia, Ltd.

The laboratory is equipped with:

- 3D CMM Zeiss Eclipse.

- Contourecord 1700 SD3 ZEISS.

- Surface roughness tester – Mitutoyo SJ400.

- Renishaw laser interferometer XL80.

Laboratory of Technological Parameters Measurement

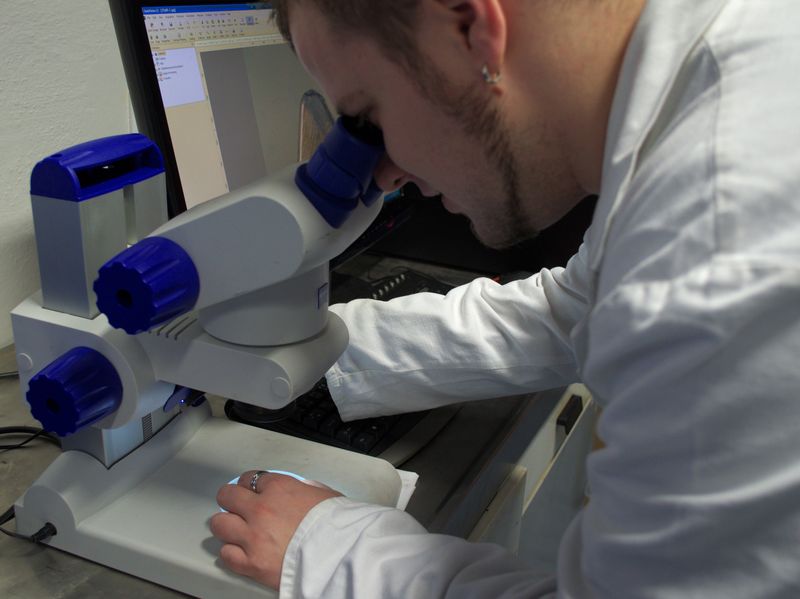

The laboratory focuses on studying fundamental technological parameters, including surface roughness, integrity, and wear of cutting materials, among others.

The laboratory is equipped with:

- Confocal microscope ALICONA Infinite Focus 5.

- Tool sorting device ZOLLER V750.

- Measurement computer with a high-speed USB measurement card, Advantech, and LabView software.

- Hardness tester for measuring HB hardness.

- 3D STAMI 2000 ZEISS Stereomicroscope.

Laboratory of Technological Procedures Identification

The laboratory is ...

The laboratory is equipped with:

- PC with A/D converter.

- Abbe length gauge.

- Roughness tester Hommel Tester T2000.

- Straightness measurement device MP125.

- Microscope BK5.

- Electronic length gauge probe TESA.

- Frequency converter Altivar 31.

- Surface quality measuring devices from HOMMELWERKE and MITUTOYO.

- Measurement computers with high-speed measurement cards from Advantech and DASY Lab software.

Laboratory of Mechanical Metrology I

The laboratory is dedicated to...

The laboratory is equipped with:

- Measurement microscope.

- Horizontal and vertical length gauge ZEISS, MITUTOYO – roughness tester.

- Height gauge, profile projector, and other measuring tools and instruments commonly used in industrial laboratories.

Laboratory of Digital Manufacturing

The laboratory is focused on...

The laboratory is equipped with:

- High-performance PC with dedicated graphics.

- Software: NX, SolidCAM, SolidWorks.

Laboratory of Mechanical Metrology III

The laboratory focuses on... The laboratory is equipped with:

- TALYROND 73 – a device for measuring roundness deviations.

Laboratory of Grinding and Finishing Technologies

The laboratory specializes in studying finishing operations and the associated phenomena involved in grinding and finishing processes.The laboratory is equipped with:

- Flat grinder BPH20.

- Sphere grinder BUD 750.

- Polisher.

- Bomar 275 saw.

- Magnetic table Tecnomagnete SpA.

- Electrochemical marking device METALTECH ME 3000 T.

- Extraction device POC 14.

- Demagnetization device HO2.

- Manual bending device XK – 2000 2A.

- Devices and equipment for residual stress measurement.

Computer Laboratory and Classroom DMPT 1 (PP019)

Computer Laboratory and Classroom DMPT 2 (BB108)